Inquiry

Form loading...

Cobalt sulphate is a critical compound widely used in various industries, particularly in the manufacturing of rechargeable batteries and catalysts. As the demand for electric vehicles and renewable energy technologies skyrockets, the necessity for cobalt sulphate is projected to grow significantly. According to a report by the International Energy Agency (IEA), global demand for cobalt in battery applications is expected to reach nearly 450,000 tons by 2030, underscoring the importance of safe handling and storage methods for cobalt sulphate to mitigate health and environmental risks.

In terms of safety, the handling of cobalt sulphate requires adherence to strict guidelines, as improper management can lead to exposure risks. The Occupational Safety and Health Administration (OSHA) notes that cobalt compounds can be hazardous if inhaled or ingested. Therefore, it is essential for industries to implement effective safety measures and educate employees on proper handling techniques. Furthermore, understanding the best storage practices for cobalt sulphate can help maintain its stability and ensure a secure working environment. By prioritizing safety and adhering to recommended guidelines, organizations can effectively utilize cobalt sulphate in their operations while minimizing potential hazards.

Cobalt sulfate is an inorganic compound with the formula CoSO₄. This bright blue crystalline material is commonly used in various industrial applications due to its unique chemical properties. As a source of cobalt, it plays a significant role in the production of batteries, pigments, and catalysts. The compound typically exists in a heptahydrate form (CoSO₄·7H₂O), which is soluble in water, making it easy to incorporate into different chemical processes.

The chemical properties of cobalt sulfate contribute to its effectiveness in these applications. It features a divalent cobalt ion (Co²⁺) that can readily form complexes with other molecules, which is beneficial in catalytic processes. Additionally, cobalt sulfate can participate in redox reactions, enabling its use in electroplating and the synthesis of other cobalt compounds.

Due to these attributes, cobalt sulfate is essential in industries ranging from electronics to agriculture, where it provides vital nutrients in soil amendments. Handling this compound safely requires proper storage conditions, such as maintaining it in a cool, dry place and using appropriate personal protective equipment to avoid inhalation or skin contact.

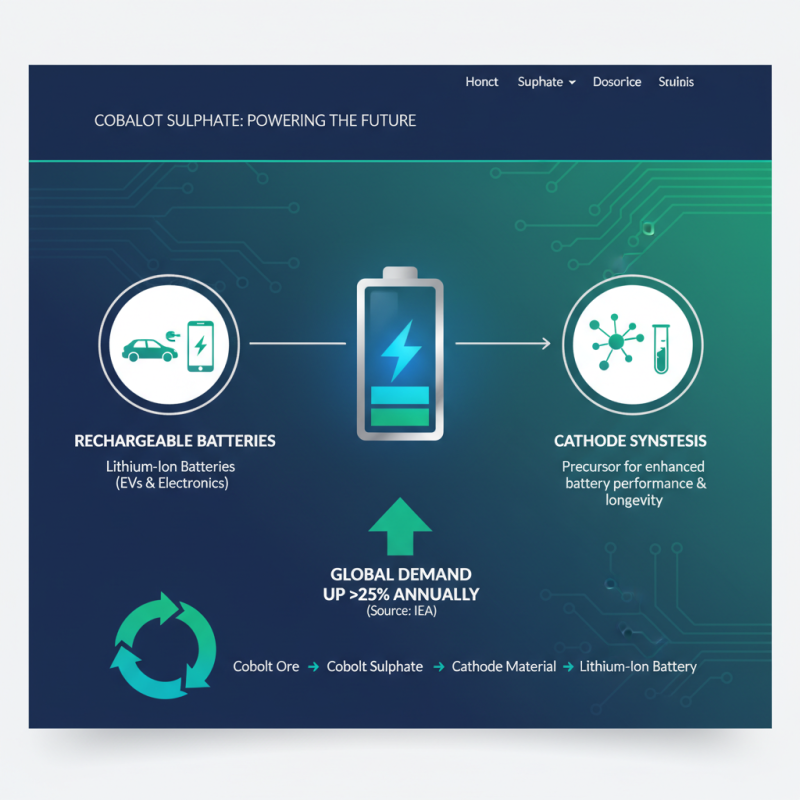

Cobalt sulphate is a vital compound utilized across various industries due to its unique properties and versatile applications. One of the most significant uses of cobalt sulphate is in the production of rechargeable batteries, specifically lithium-ion batteries. According to a report by the International Energy Agency, the demand for electric vehicle batteries is expected to increase by over 25% annually, driving up the need for cobalt-based materials. Cobalt sulphate serves as a precursor in the synthesis of cathodes, providing enhanced performance and longevity to battery systems.

In addition to its role in battery production, cobalt sulphate is instrumental in the manufacturing of pigments and catalysts. The construction and automotive industries benefit from cobalt-based pigments, which are valued for their vibrant colors and stability under various environmental conditions. The pigment industry is projected to grow at a CAGR of approximately 4.5% by 2025, underscoring the importance of cobalt sulphate in producing high-quality products that meet industry standards. Furthermore, cobalt sulphate is also used in electroplating processes, contributing to improved corrosion resistance and wear protection for metal surfaces in various applications.

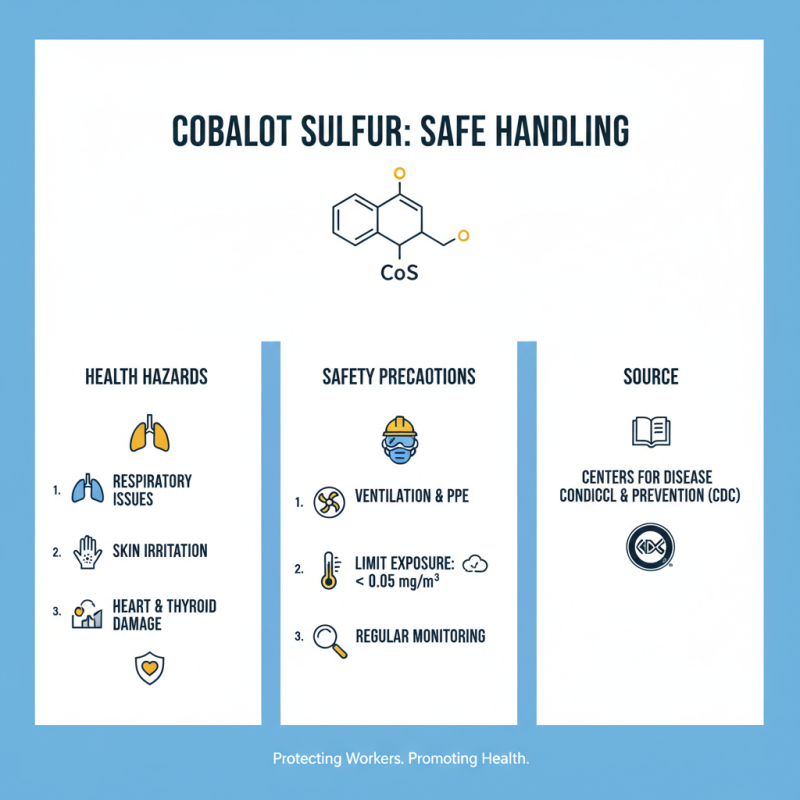

Cobalt sulphate, commonly used in various industrial applications, poses certain health hazards that necessitate stringent safety precautions during handling. According to the Centers for Disease Control and Prevention (CDC), exposure to cobalt compounds can lead to respiratory issues, skin irritation, and in severe cases, damage to the heart and thyroid gland. Industrial hygiene standards recommend maintaining cobalt exposure levels below 0.05 mg/m³ to safeguard workers in environments where cobalt sulphate is present. Regular monitoring and assessment of airborne concentrations are essential in workplaces to prevent adverse health effects.

To minimize risks associated with cobalt sulphate, several safety practices should be implemented. Personnel handling this compound should wear appropriate personal protective equipment (PPE), including gloves, masks, and protective clothing, to mitigate skin and respiratory exposure. Additionally, proper ventilation in storage areas is critical to disperse any airborne dust or fumes. According to the National Institute for Occupational Safety and Health (NIOSH), employers should provide training on emergency procedures and potential health effects to ensure that all workers understand how to handle cobalt sulphate safely. Thorough understanding and implementation of these precautions can significantly reduce the risk of health hazards associated with this chemical.

When it comes to storing cobalt sulfate safely, the first consideration should be the environment in which it is placed. Cobalt sulfate should be kept in a cool, dry, and well-ventilated area to prevent any reaction with moisture or extreme temperatures. It is essential to use containers that are compatible with the chemical, typically those that are corrosion-resistant and sealed tightly. Labeling the storage area and containers clearly with appropriate hazard warnings is also crucial to ensure safety for anyone who might handle the material.

Additionally, maintaining an organized inventory is vital for safe storage practices. Use a first-in, first-out (FIFO) system to ensure that older stocks are used before newly acquired ones, minimizing the risk of degradation over time. Regularly inspect the storage area for any signs of leaks, spills, or improper sealing of containers, addressing any issues promptly to maintain a safe environment. Additionally, ensure that appropriate personal protective equipment (PPE) is available and understood by all personnel involved in handling cobalt sulfate to mitigate any risk during use or transfer.

When dealing with cobalt sulfate, proper disposal of waste and contaminated materials is crucial to ensure environmental safety and compliance with regulations. Cobalt sulfate, being a hazardous material, should never be discarded with regular waste. It is essential to establish a dedicated waste disposal protocol that includes the collection, labeling, and confinement of cobalt sulfate waste. This process typically involves utilizing designated waste containers that are clearly marked and resistant to leakage, minimizing any risk of contamination to surrounding areas.

In addition to proper containment, it is important to consult with local environmental agencies to understand the specific regulations regarding cobalt sulfate disposal in your area. Many jurisdictions require that hazardous waste be disposed of at licensed hazardous waste treatment facilities. Before disposal, materials should be assessed for their contamination levels, and any waste should be characterized to determine appropriate disposal pathways. It is advisable to keep thorough documentation of all handling and disposal activities to ensure accountability and regulatory compliance. Following these guidelines helps mitigate the risks associated with cobalt sulfate, protecting both human health and the environment.